What is Polyester DTY Slub Yarn?

Polyester DTY slub yarn is a transformative innovation in the textile industry that has received widespread attention and praise, fundamentally changing the pattern of fabric production and consumer perceptions. Throughout the course of this article, we will fully explore the multifaceted dimensions of this extraordinary yarn, delving into its complex composition, the nuances of its manufacturing process, its diverse applications across industries, and countless other fascinating aspects that contribute to Its growing importance in the field profiles.

Manufacturing Process of Polyester DTY Slub Yarn:

Polyester DTY slub yarn is primarily composed of polyester, a synthetic polymer known for its durability and versatility. Polyester fibers undergo a stretch texturing process that produces yarn with intentional irregularities called slub yarn. These slubs give the yarn a unique texture and appearance that sets it apart from regular polyester DTY yarns. The following is the manufacturing process of polyester DTY slub yarn:

Polymerization: The process begins with the polymerization of polyester. The raw material is usually derived from petroleum and is chemically processed to form polyester chips.

Melting and extrusion: Polyester chips are melted and extruded through a spinneret to form filaments. These filaments serve as the basis for subsequent stages.

Painting: The filament undergoes a drawing process in which it is stretched to align the molecular chains, thereby increasing strength and elasticity. This step is crucial to the overall quality of the yarn.

Texturing: The stretched filaments are then texturized. For polyester DTY slub yarn, this involves introducing intentional irregularities or slubs into the yarn. Various techniques are used to achieve this textural effect.

Cooling and shaping: The textured yarn is cooled and shaped to stabilize its structure. This step ensures that the slub effect is preserved and that the yarn maintains its unique texture throughout the subsequent process.

Twisting: To increase strength and stability, yarns can undergo a twisting process. This step also affects the final appearance of the yarn and therefore its overall texture.

Winding & Packaging: The final polyester DTY slub yarn is wound onto spools or cones, ready for distribution and use in a variety of textile applications. Careful packaging is essential to prevent damage and maintain the integrity of the bamboo effect.

Unique Features of Polyester DTY Slub Yarn:

Deliberately introduced irregularities during the manufacturing process give polyester DTY slub yarn its unique properties. These bamboo sections create a textured and uneven appearance, adding depth and visual interest to the fabric. The result is a yarn that not only meets functional requirements but also provides creative and aesthetic advantages to textile products.

Essentially, the composition and manufacturing process of polyester low-stretch slub yarn combines scientific precision with artistic intent to produce a textile material that redefines what is possible in fabric design and production.

Application of Polyester DTY Slub Yarn in Various Textile Products

Polyester DTY slub yarn is a versatile material with multiple applications in the textile industry, each exhibiting its unique properties. Let's delve into its many uses, focusing specifically on window screens.

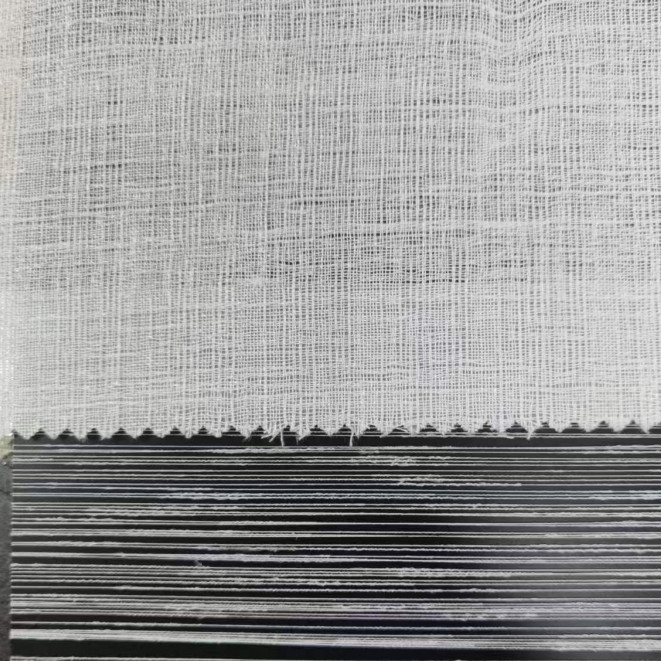

1. Window Screen:

Polyester DTY slub screens find innovative applications in the manufacture of window screens. The bamboo effect not only adds an interesting visual texture but also enhances the functionality of the screen. The durability and lightweight nature of the slub screen make it an ideal choice for window screening, providing an effective insect barrier while allowing for proper ventilation.

2. Seat Cushion:

The unique texture of slub yarn enhances the beauty of the seat cushion. Whether used for indoor furniture or outdoor patio seating, the bamboo effect adds a touch of sophistication to cushions while ensuring durability and comfort.

3. Sofa Release:

Polyester DTY slub yarn is used to make sofa fabrics to enhance the appearance of living room furniture. The textured surface brings a modern and stylish element to the sofa, making it the focal point of the interior design.

4. T-shirt:

In the field of clothing, T-shirts made of slub yarn are a popular choice. The intentionally irregular shape of the yarn creates a relaxed, casual look, making the bamboo tee a stylish and comfortable option for everyday wear.

5. Upper:

Designers often use polyester DTY slub yarn in the production of shoe uppers. Unique textures enhance the visual appeal of footwear, adding an extra layer of interest to a variety of footwear styles, from sneakers to casual and fashionable shoes.

6. Socks:

Even in the field of socks, slub yarn has left its mark. Socks made from slub yarn combine comfort and style, and the textured yarn adds a dynamic element to typical sock designs.

Each of these applications demonstrates the adaptability of polyester DTY slub yarn in meeting the diverse needs of different textile products. Whether it is enhancing the beauty of furniture, providing comfort to clothing, or adding a stylish touch to accessories, slub yarn continues to redefine and enhance every aspect of the textile industry.

Tips for Using Polyester DTY Slub Yarn

Working with polyester DTY slub yarn requires a detailed understanding of its unique properties to realize its full potential in textile projects. Manufacturers and designers alike can benefit from a range of practical tips to ensure the best results from the manufacturing process and final product.

Manufacturing Precision: Precise control is critical when incorporating polyester DTY slub yarn into the manufacturing process. Attention to detail during the stretching and texturing stages was crucial to achieving the desired slub effect. Manufacturers should carefully calibrate parameters such as temperature, tension, and speed to ensure uniform irregularities in the yarn. Additionally, consistent monitoring during the twisting and winding stages helps maintain the integrity of the bamboo texture. This precision not only enhances the beauty of the final product but also ensures the durability and functionality of the slub fabric.

Considerations for Designers and End-Users: Designers and end-users should be aware of the unique properties of polyester DTY slub yarn when planning and conducting projects. The intentional irregularity of slub yarn contributes to its unique appearance, which designers can exploit to create visually striking textured fabrics. However, the intended use of the final product must be considered; for example, some projects may benefit from a more pronounced bamboo effect, while others may require a more subtle texture. Additionally, end users should follow recommended care guidelines to maintain the longevity and appearance of fabrics made from slub yarn. This collaborative approach between manufacturers, designers and end-users ensures that polyester DTY slub yarn is used efficiently to produce high-quality, beautiful textiles.

In Conclusion

In conclusion, polyester DTY slub yarn has become a game changer in the textile industry, providing a unique and textured alternative to ordinary yarns. From its composition and manufacturing process to applications, market trends, and environmental impact, slub yarn has proven its versatility and relevance. As the demand for unique and personalized textiles continues to grow, slub yarn is likely to maintain its status as a sought-after choice among designers and manufacturers.

The above briefly introduces some relevant information about polyester DTY slub yarn. If you want to know more about polyester DTY slub yarn, or if you want to buy polyester DTY slub yarn, please contact us.

As a professional yarn manufacturer, Poyarn can provide suppliers and manufacturers with Doris, slub yarn, hollow yarn, etc., which greatly meets the needs of customers in the fields of window screens, cushions, sofa cloths, T-shirts, shoe uppers, socks, etc. Textile demand. We have two professional curtain fabric and slub yarn production lines. It has 24 tatting rapier looms, more than 30 Titan TT-828 digital rapier looms, and 20 texturing machines imported from Japan. It can not only meet the production of 50D-600D semi-dull dolly slub yarn, 170D-540D imitation slub yarn, 150D-2000D air textured yarn, air textured slub yarn, but also meet the needs of recycled yarn and customized spinning.